-

gold recovery equipment

gold recovery equipmentDetails of gold recovery equipment

1. Function introduction: The electrolytic gold extraction machine is a technology for wet refining and purification of metals. It can selectively electrolyze valuable metals and is especially suitable for the selective electrolysis (electrolysis) of low-content solutions and solutions with complex components in the metallurgical industry. (accumulation) separation and purification, as well as the recovery of heavy metal ions in wastewater.

2. Technical advantages of gold ecovery equipment:

1)It has the ability to process low-concentration metal solutions, and has higher production efficiency than traditional electrolysis technology to enrich valuable metals in a wider range, from a few tenths of a gram/liter to a few hundred grams/liter of metal concentration for electrolytic production and metal The ability to separate. In particular, it has unparalleled technical advantages in copper-nickel separation and copper-silver separation;

2) It has stronger adaptability to pollutants in the solution and can extract high-purity metals from solutions containing impurities;

3)It has the ability to extract a variety of metals and has the ability to selectively electrolyze metals, and can produce different forms of cathode products (sheets or metal powders) according to the concentration of the solution;

4) The equipment is modular and easy to operate.

-

platinum group metals refining/refinery line

platinum group metals refining/refinery lineplatinum group metals refining/refinery line Introduction:

Given the scarcity of domestic platinum group minerals and supply-demand imbalances, China depends mainly on imported resources to meet its needs. However, in recent years, a significant portion of domestically available platinum group metals comes from the recycling of industrial waste materials, such as platinum catalysts used in the petrochemical industry and catalytic converters from car exhaust systems. Different raw materials require different processing technologies and equipment. Based on the characteristics of each raw material, our company designs tailored processes and equipment to meet production requirements.

In September 2021, a collaborative project between our company and Northeast Normal University, titled "Short Process Cleaning and Efficient Separation and Refining Technology and Equipment for Platinum Group Metals," received recognition from Professors He Jieqiong and Huang Xiaowei. This project has been acknowledged by the Non-ferrous Metals Industrial Association of China as being on par with international advanced levels.

-

carbon-separating screen

carbon-separating screenFeatures of Carbon-separating screen

This product is installed in the carbon-immersing tank, with the function of separating the ore pulp from the activity

Notes for Selection

Please specify the model and quantity, as well as the model and material of screen cloth while placing your order. If there is no special requirement, we will make the screen in accordance with the manufacturer's drawings.

We can design and make the screen as per the customer's special requirements.

Technical parameter list of carbon-separating screen

型号

筛子直径(mm)

筛架长度(mm)

筛孔规格(目)

重量(kg)

JQ300

⌀300

1000

28

20

JQ500

⌀500

1000

20

35

-

multi wash thickener

multi wash thickenerFeatures of Multi (wash) thickener:Multi wash thickener is mainly used in the washing proces in gold cvanidation plant, With multi-stage countercument washing, it can work continuously. Its features: reliable running, convenient management, low dynamic power, and reducing foor space required greatly.

Notes for model selection:

Usually, concrete tank is adopted. If the tank lined with steel plate is required, we can provide drawings according to thecustomer's demands, and the customer shall make the tank by himself at the field.

Technical parameter list of multitray(wash) thickener:

Standard Model

Pond for concentration

Sediment area(m2)

Speed of frame(r/min)

Productive capacity(t/d)

Transmission Motor

Dimension(LxWxH)(mm)

Weight(kg)

Dia (m)

Depth (m)

Model

Power(kW)

Speed(r/min)

7 metres 3 tiers

7

9

115.5

0.2481

15~50

Y112M-6

2.2

940

8500x8500x10218

14200

7 metres 4 tiers

7

9.5

154

0.2481

15~50

112M-6

2.2

940

8500x8500x12679

16089

9 metres 3 tiers

9

6.8

191

0.28

≤88

Y132M2-6

5.5

960

11090x10000x11740

21900

12 metres 3 tiers

12

7.23

339

0.2

≤160

Y132M2-6

5.5

960

15500x12000x10600

40400

-

pickling agitating tank

pickling agitating tankFeatures of pickling agitating tank:

RJS pickling agitating tank is a kind of special equipment for removing the materials accumulated on the surface of activecarbon, such as calcium carbonate, by using the diluted hydrochloric acid. It is a kind of agitating tank improved on the basis of RJ agitating tank, With specially designed impeler, its abrasion to the carbon is low, Its shaft and impeller are made of stainless steel.

Notes for Selection

While placing your order, please specify the model and quantity, as well as the material of the tank. The tank many bemade of stainless steel or anticorrosion treated common steel plate, at the customer's option.

Technical parameter list of RJS pickling agitating tank

槽体尺寸(mm)

Size of trough

有效容积(m°)

Effective

volume

叶轮直径(mm)

Impeller Dia

转速(r/min)speed

电动机 Motor

外形尺寸(mm)

Dimension

(LxWxH)

机器总重

(kg)

Total weight

直径Dia

高度Heigh

型号

Model

功率(kW)

Power

1000

1000

0.7

240

238.3

Y100L-6

1.5

1198x1198x2130

531

1500

1500

2.2

400

142

Y132S-8

2.2

1798x1798x2880

955.4

-

air elevator

air elevatorFeatures of carry carbon pump:This product is a kind of special equipment designed for lifting the activated carbon with gold from carbon-immersingtank during absorbing and refining the gold with carbon.It has a scientific structure and small damage to the carbon.

Air elevator(Carry Carbon Pump)Technical parameters

型号

Model

吸炭管规格

Size of the suction

空气管规格

Size of the air pipe

应用范围

Application range

KQT-3

2"

3/4"

SJ2.5x3.15,SJ3x3.15,SJ3x3.5,SJ3.15x3.55,SJ3.55x4

KQT-7

108x4

48x4

SJ4x4.5, SJ4.5x5

Note: The length of suction pipe may be different according to different size of leaching tank

-

agitating carbon-immersing tank

agitating carbon-immersing tankFeatures of Dual impeller high-efficient agitating carbon-immersing tank:

This product is used in carbon paste flow and cyanidation process. The carbon-immersing tank should match other auxiliary devices like carbon-separating screen, and recessed impeller pump, etc. Its structural features:the upper and lower layer of impellers are of steel plate encapsulated with rubber, which are connected by means of bolts, with the features like good equilibrium, easy replacement, and long service life. The main shats are divided into the upper layer and the lower layer, which areconnected by means of locating flanges, able to reduce the lifting height; inlate at several points dispersingly, with good air mixing performance.

Notes for Selection:

Planet cycloid reducing motor is usually adopted for driving, with the features like simple structure and low price. If gear wormdrive is required, please order it specially and specify it.

Technical parameter list of Dual impeller high-efficient agitating carbon-immersing tank

型号

Model

槽体规格(mm)

直径

*高度

Size of the tank

D*L

有效容积

m3

Efective

capacity

叶轮转速

(r/min)

Revolution of impeller

叶轮直径

(mm)

Diameter of impeller

给矿管直径

(mm) Diameter of feeding pipe

排矿管直径

(mm)

Diamete of discharging pipe

行星摆线减速器

重量

(kg)

Weight

型号Model

速比

Speed ratio

配用电机功率(kW) Motor power

⌀2 5 X 2 5

2500x2500

6

52

800

2- ⌀133

2- ⌀133

XLD2 2-4-29

29

2.2

2800

⌀2 5 X 3 15

2500x 3150

13

52

935

2-⌀125

2- ⌀133

XLD2 2-4-29

29

2.2

3120

⌀3 X 3.15

3000x 3150

18 93

43

1130

2-⌀150

2- ⌀150

XLD4-5-35

35

4

5300

⌀7.5x8.0

7500x8000

268.6

21

2900

2-⌀159*8

2-⌀159*8

XLD22-10-47

47

22

32796

⌀8.0x 8 5

8000 X 8500

342

16.4

3200

2-⌀159*8

2-⌀159*8

XLD22-11-59

59

22

42467

-

deoxygenation tower

deoxygenation towerFeatures of deoxygenation tower:

Deoxygenation tower is a kind of vacuum deoxidation equipment used for eoxygenating before cyanidation pregnant solution displacement. It is equipped with spray thrower and leveling device. A batten grid structure is adopted for its packing layer, with good and hesivity anddeoxygenation effect better than that of plastic packing.

Notes for Selection:

It doesn't include a vacuum device.

Technical parameter list of Deoxygenation tower

规格Standard

处理介质

Handing medium

工作温度

Work temperature

喷淋量(m3/m2·h)

Capacity of spraying

重量(kg)

Weight

⌀7000x3000

氰化贵液

Cyanide liquor

常温

Room temperature

16~37.5

550

⌀1000 x3000(3500)

700(774)

⌀1400x4400

230

-

desorption electrolysis equipment complex

desorption electrolysis equipment complexFeatures of desorption electrolysis equipment complex:

Desorption electrolysis equipment complex is a kind of key equipment in the cyanidation carbon-in-pulp gold refining process in gold mines. lt is a kind of integral equipment complex consisting of electric heater, desorption post, heat exchanger, whole electrolytic bath, and pump, with the features like compact structure, convenient installation, desorption rate reaching 96% and over, and electrolysis rate more than 99%.

Notes for selection:

We can design and make the products of different specifications according to the customer’s requirements.

Technical parameter list of movable desorption electrolytic equipment:

解吸率(%)

Desorption

rate

电解率(%)

Electrolysis

rate

装机容量(kw)

Installed

capacity

解吸温度(℃)

Desorption

temperature

电解电压(v)

Electrolysis volt

电解电流(A)

Electrolysis

current

生产能力

(kg/批)

Productive capacity

电解液流量

(t/h)

Electrolysis

equid flow

>96

99

30

95

1.5-3(直流)

200

300

1.5

-

electrowinning/electrorefining tank

electrowinning/electrorefining tankRotating Electrode Technology and Conventional Electroplating Technology share the same electrochemical theoretical foundation. Both involve immersing the anode and cathode in an electrolyte solution containing target metal cations, achieving directed movement of ions under electric fields to deposit the target metal on the cathode.

The difference lies in that rotating electrode devices allow for higher flow velocity of the electrolyte solution, effectively utilizing the rapid flow of the electrolyte to eliminate concentration polarization phenomena during the electroplating process. This ensures more complete reaction and high purity of cathodic products with high current efficiency. It is particularly suitable for (wet metallurgical industry) in the selective electrolysis (electroplating) separation and purification of low-concentration and multi-component electrolyte solutions, or for removing metal ions from wastewater.

Applications:

1、Copper refining waste liquid purification;

2、Copper corrosion solutions copper recovery;

3、Zinc smelting slag copper and nickel recovery;

4、Copper, cobalt, nickel, zinc mixed metal ion solution copper, cobalt, nickel recovery;

5、Cyano solutions electrorefining Au and Ag recovery。

-

gold chemical refining equipment

gold chemical refining equipmentThe chemical refining of gold usually involves dissolving crude gold in aqua regia or a sodium chlorate-hydrochloric acid solution. Sodium sulfite or other reducing agents are then introduced for potential-controlled reduction, producing 99.99% pure gold.

-

copper leaching system

copper leaching system1、Customer demand

The metal copper in copper ore is extracted by physical and chemical methods, and a theoretical and practical process is found for extracting copper from copper ore.

2. Basic customer data

Feed type

Copper production

Product shape

process mode

Solution copper content

Effluent copper content

20% copper ore concentrates powder

100 kg

Copper sulfate solution

Batch processing

5-20%

20g/L

Copper sulfate solution

100 kg

Electrolytic copper plate

Batch processing

10-40g/L

2g/L

3.Process introduction

The experiment was mainly carried out in three steps:

In the first step, the copper metal in the copper ore is dissolved in the liquid, and the solid copper metal is converted into the free ion state;

The second step, the solution of dissolved copper is filtered to remove impurities;

The third step is to extract and purify the copper in the copper containing solution. The result is a high purity copper sheet.

4.Experimental Process:

1.Configure the concentration of about 10% to 15% concentration of dilute sulfuric acid

solution standby.

2.A certain amount of copper ore is weighed and crushed, and the crushed copper ore powder is placed in dilute sulfuric acid. After the copper ore is put into dilute sulfuric acid,

a violent reaction occurs in the solution, some gas emerges, and the copper ore slowly dissolves. The color of the potion turns cloudy.

3.Add an appropriate amount of oxidant to accelerate the dissolution of copper in the ore powder.

4.After about 1 hour,the solution appears stratified, green clear liquid appears on the upper layer,and very colored insoluble solid or sludge appears on the bottom.

5.The precipitation was filtered and separated, and the green liquid was filtered out.

6.The copper content of the green filtrate was analyzed, and the concentration of copper ion reached 40g/L. High copper content.

7.The electrolysis experiment was carried out on the green copper filter liquid, with the filter

liquid as the electrolyte, titanium plate as the anode and stainless steel plate as the cathode.

8.A certain intensity current is applied to the anode and cathode plate for electrolysis, and a

copper substance appears on the cathode plate and is attached to the cathode stainless steel plate. Continue electrolysis.

-

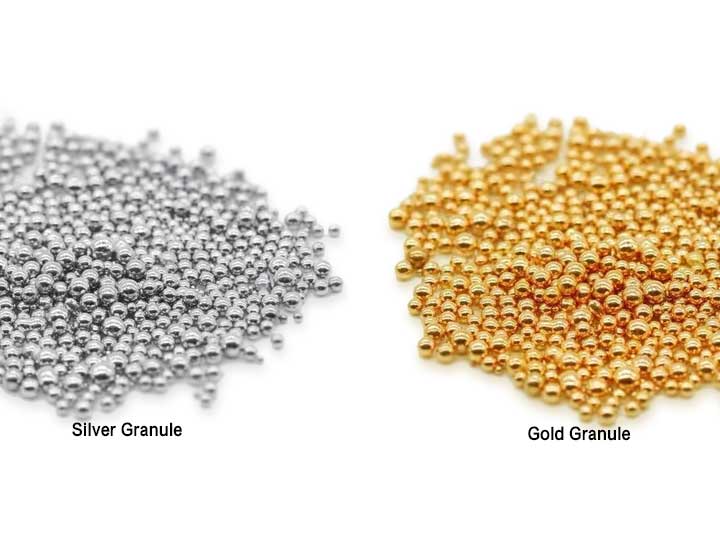

vacuum granulator

vacuum granulator20-50kg Vacuum Granulator (With Mechanical Stirring):

Anti-Oxidation: Inert gas protection during melting minimizes alloy oxidation.

Uniform Color: Mechanical stirring ensures even product coloration.

High-Quality Output: Vacuum granulation yields low oxygen content, no water trapping, and excellent sphericity.

Precise Temperature Control: Intelligent digital control with a temperature deviation of ±2°C.

Secondary Feeding: Allows additional material input under vacuum to ensure complete metal melting.

Next-Gen Operating System: User-friendly interface with streamlined one-touch operation.

Equipment Specifications:

Model

Voltage

Power

Max Temp

Melting Time

Gas Used

Max Capacity

Applicable Metals

Cooling

Vacuum Pump

Dimensions

Weight

JQ-GVS20

380V

30KW

1600°C

10min

Argon/Nitrogen

20KG(Gold)

Gold, Silver, Copper, Alloys, Aluminum, Tin, etc

Water-cooled

63m3 /hour

1180*1000*2050mm

~360KG

JQ-GVS30

380V

45KW

1600°C

12min

Argon/Nitrogen

20KG(Gold)

Gold, Silver, Copper, Alloys, Aluminum, Tin, etc

Water-cooled

63m3 /hour

1180*1000*2050mm

~380KG

JQ-GVS50

380V

75KW

1600°C

15min

Argon/Nitrogen

50KG(Gold)

Gold, Silver, Copper, Alloys, Aluminum, Tin, etc

Water-cooled

63m3 /hour

1180*1000*2050mm

~400KG

-

copper recovery equipment

copper recovery equipmentThe copper electrolysis system uses the latest permanent cathode technology, completely replacing the Initial electrode plate electrolysis process; high-dimensional precision ethylene-base epoxy resin is used for the entire electrolysis tank, replacing the original glass electrolysis tank to accelerate material turnover.

Simultaneously, ground communication is added, enabling wireless information exchange between crane, machinery, and electrolysis tanks during assembly status; AGV small car intelligent transfer is adopted for output lines to optimize material transportation scheduling; constant brightness control and human body sensing technologies are applied to achieve smart lighting and reduce energy consumption; monitoring of equipment operation status, automatic generation of data reports and statistical analysis are implemented.

Copper Recovery Euipment Project Case:

High-density Copper Electrolysis Tank Model Marameters:

Model

Copper Output Capacity

Other

Power

Materials

JQ-JDJ-20

20kg/d

depending on operating conditions

380V

PPH

JQ-JDJ-50

50kg/d

JQ-JDJ-100

100kg/d

-

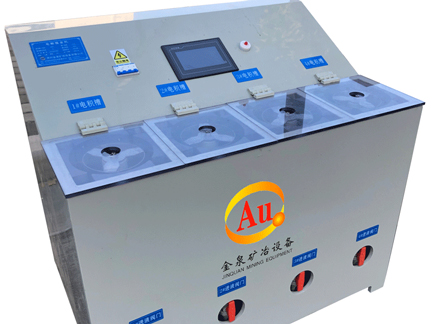

gold recovery machine

gold recovery machineInstruction Of Gold Recovery Machine:

The new version gold recovery machine an intelligent touch screen, low-voltage extraction technology, supports fully automated intelligent operation, and offers automatic/manual mode.

The JQ series uses electrolysis to adsorb gold, silver, copper, and other precious metal ions from solutions onto the cathode. Once a certain weight is adsorbed, the precious metal sheets (gold, silver, copper, etc.) are stripped from the cathode. This equipment enables safe and efficient refining and recovery of various solutions containing gold, silver, or copper, ultimately converting the ions in the solution into pure precious metal form.

Product Advantages:

1、High-efficiency recovery of gold, silver, copper, and other valuable metals;

2、Precious metal purity ≥ 99%, with an ion recovery rate ≥ 99%;

3、Low-voltage extraction, highly efficient, and odor-free.

Model Specifications:

Model

JQ-DJC-L3

Product Name

Gold Recovery Machine

Dimensions

43 x 29 x 58 cm

Rated Voltage

220 V

Power

120 w/h

Weight

45 kg

Capacity

18 L~oo

-

gold extraction machine

gold extraction machineProduct Introduction of Gold Extraction Machine:

Swirl electrowinning is a wet metallurgical technology used for the selective electrowinning and extraction of gold. It is particularly suitable for the selective electrolytic separation and purification of valuable metals from low-concentration or complex-composition solutions in the metallurgical industry, as well as for the recovery of gold from wastewater.

Advantages of Gold Extraction Machine:

1)、Capable of processing low-concentration metal solutions with higher production efficiency compared to traditional electrolytic technologies. It can enrich valuable metals across a wide range of concentrations, from fractions of a gram per liter to hundreds of grams per liter, especially excelling in copper-nickel and copper-silver separation.

2)、Strong adaptability to pollutants in solutions, enabling the extraction of high-purity gold from impure solutions.

3)、Capable of extracting multiple metals with selective electrolysis, and able to produce cathode products in different forms (plates or metal powders) depending on solution concentration.

4)、Modular equipment design with simple operation.

Model parameters of gold extraction machine

Product model

Product Name

Dimensions(mm)

Rated Voltage

Power

Weight(kg)

JQ-DJC-L1

gold extraction machine

450*300*600

220V

300w/h

45kg

JQ-DJC-L3

gold extraction machine

900*1010*800

380V

1500w/h

125kg

JQ-DJC-L4

gold extraction machine

1220*1010*800

380V

2.5kw/h

150kg

JQ-DJC-L5

gold extraction machine

1520*1010*800

380V

3kw/h

180kg

Current: Single tank designed for 100A, voltage 5V.

Each small tank can process approximately 200L of solution. Single or multiple tanks can be selected based on production requirements, with processing speed varying according to concentration.Result of Gold Extraction Machine:

-

recycling precious metals from circuit boards

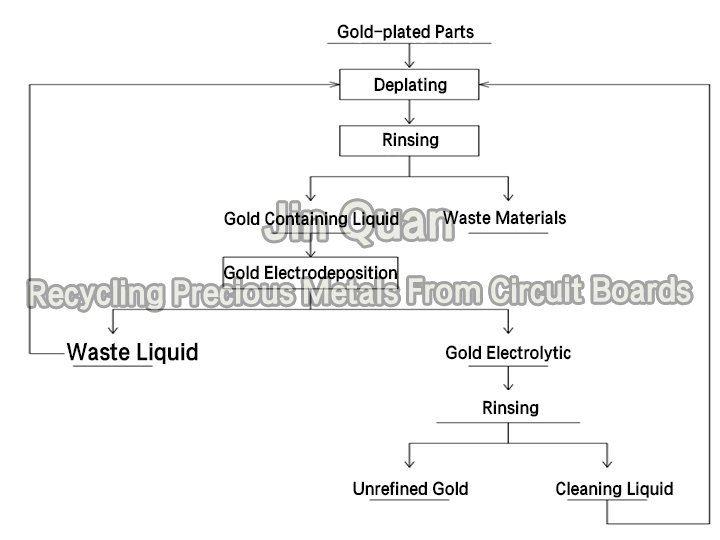

recycling precious metals from circuit boardsRecycling Precious Metals From Circuit Boards Process Description:

1)After the gold plating waste is loaded into the drum , the drum is lifted to the working position of the deplating tank (level 1 deplating tank) by a crane, and the motor is started to rotate the deplating tank.

2)After the deplating is completed, lift and drain the drum, then rinse it and enter the second level cleaning tank. Afterwards, dry it according to the actual situation.

3)After multiple de deplating processes, the gold content in the de plating solution reached a certain concentration (1.5g/L), and the solution was electrodeposited to recover gold. After electrodeposition, the gold content in the solution decreased to 0.4mg/L.

Recycling Precious Metals From Circuit Boards Process Diagram:

-

extraction of precious metals from waste circuit boards

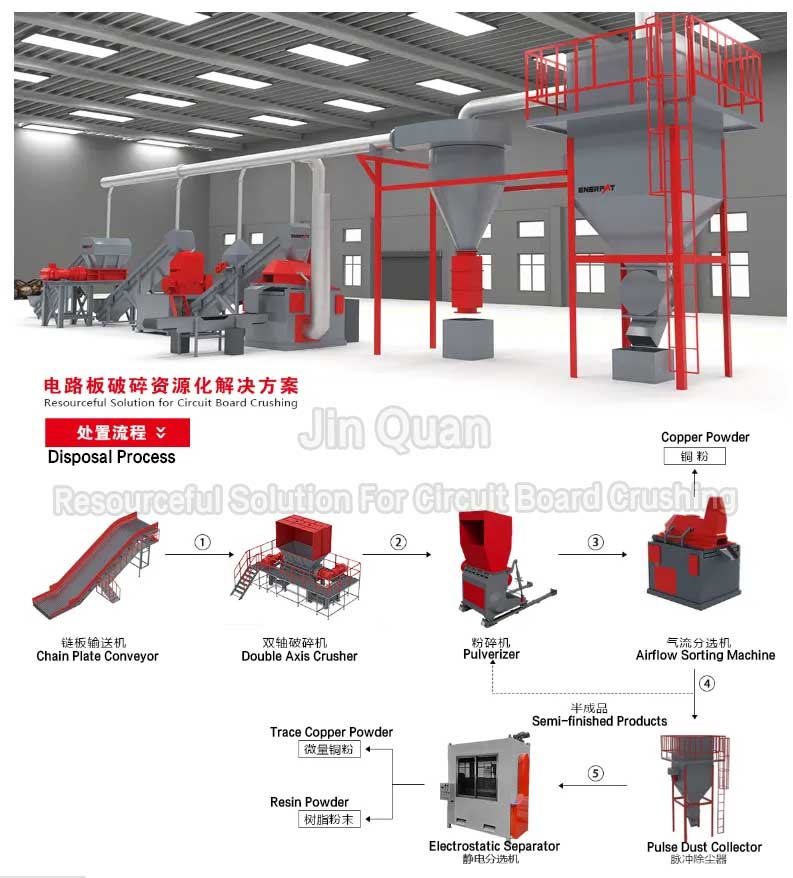

extraction of precious metals from waste circuit boardsMainly using methods or based on the differences in physical properties between materials, including density, conductivity, magnetism, surface characteristics, etc. for recycling, including processes such as disassembly, crushing, and sorting. Physical processing technology can enrich valuable substances in electronic waste, with advantages such as low cost and low pollution. However, due to the low proportion of precious metals in the total mass of printed circuit boards, it is difficult to recover high-purity precious metals using general methods. Various physical processing technologies still require subsequent processing of precious metal products. The main physical recycling methods currently used include impact crushing, extrusion crushing, shear crushing, high-speed eddy current crushing, dry screening, air shaking table, magnetic separation, electrostatic separation, pneumatic eddy current separation, and eddy current separation.

Resourceful Solution For Circuit Board Crushing:

-

copper electrolysis testing machine

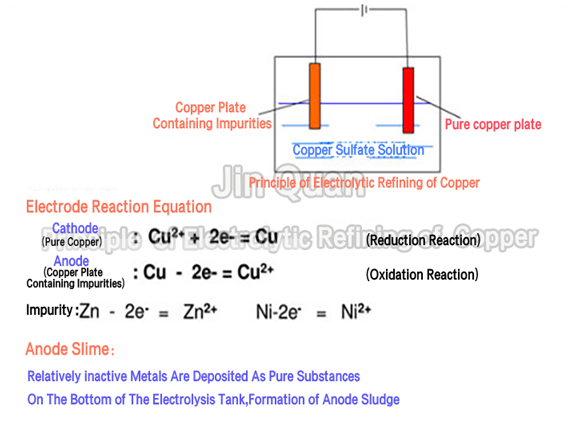

copper electrolysis testing machineThe raw material is 99.95% copper, used for experimenting in producing 99.999% pure copper. We need to design a copper electrolysis tank capable of producing 1 kilogram of copper per day.

Principle of Electrolytic Refining of Copper:

-

precious metal wet refining system

precious metal wet refining system1、Professional Sales of Gold, Silver, Palladium, and Platinum Wet Refining Reaction kettle;

2、Titanium Dissolution gold kettle, Ceramic/Titanium Reduction kettle, etc;

3、Ceramic Reaction kettle, Titanium Reaction kettle, and Accessories Such as Vacuum Filters and Storage Tanks。

-

gold purity equipment

gold purity equipmentAdvantages of the New Type gold purity equipment

1、High-quality stability: Achieves Au99.99 ingot standards; custom orders can also produce 99.999% pure ingots based on special needs.

2、Low production costs: Consumes 150 liters of AuCl per ton of gold, making it cost-effective.

3、High efficiency using advanced high current density electrorefining technology: 1200A maximum current density, with a production efficiency of up to 99%. The electroplating cycle is between 10 to 22 hours (depending on the thickness of the electrodes).

4、Equipped with smoke condensing devices: As the gold electrorefining process requires relatively high temperatures (60-70°C), the smoke condensing device efficiently recirculates evaporated electrolyte solutions, preventing gold loss and ensuring higher efficiency in the refining process.

5、High-quality materials used for the main components of the equipment: The unit is constructed using high-performance polypropylene material, while the anode and cathode electrodes are made of titanium coated with copper, providing excellent electrical conductivity.

-

vacuum continuous casting machine

vacuum continuous casting machine1600 ℃ 4-8 kg induction heating type continuous cast equipment

1. Jewelry continuous casting device is specially developed for casting high-purity gold, K gold, silver and other precious metal plates, bars, rectangular bars, circular pipes and other products

2. It adopts gas protection melting, temperature control accuracy and automatic mixing function to let the surface of the finished product shining without any pores and oxidation

3. The best casting technology and top-level equipment engineering are used to achieve the best metallurgy and high precision. The continuous casting machine is extremely fast, reliable and cost-effective

model: LS-8 power: 380V, 50/60 hz, 25kw Maximum current: 26 A Applied metal: Gold, silver, copper, and their alloys Maximum capacity: 24k 8.0 kg; 18k 6.0 kg; 925 silver 4.0 kg smelting time: 8 min application: bar: diameter 4-20 mm pipe: min 9-12mm, max 52-60mm block: min T5xW5mm, max T20x W70mm maximum temperature: 1600 ℃ K-type thermocouple: 1100℃ Maximum pulling speed: 40 cm/min Machine size: 1120x840x1560 mm Machine weight: 205 kg Shielding gas: Nitrogen or argon heating system: induction heating Temperature control system: PID Temp Accuracy: +-2℃ -

silver electrolytic unit

silver electrolytic unitSilver is a metal with excellent beauty and conductivity, and is widely used in jewelry, electronics and industry. However, the requirements for its purity are different. The purity of traditionally traded silver is 99.99%, and electrolysis is a very good way to purify it.

The characteristics of 925 silver are that it does not deform and is durable. High-purity silver is widely used in the electronics industry.

Electrolytic purification uses potential difference and chemical reactions: Anode reaction (oxidation reaction):

Ag(s)→Ag⁺+ e﹣

Silver loses electrons at the anode to form silver ions (Ag⁺).

Cathode reaction (reduction reaction):

Ag⁺+ e﹣ →Ag(s)

Silver ions gain electrons at the cathode and are deposited as metallic silver.Potential difference control: The standard electrode potential of silver is +0.7996V, but the actual operating voltage is usually between 2 and 5 volts to overcome solution resistance and other electrochemical resistances to ensure efficient deposition of silver. Thus, the purpose of purifying pure silver can be achieved.

Silver can be purified by electrolysis, and an automated control system can be further adopted to achieve unmanned operation and reduce labor.

-

gold wet refining equipment

gold wet refining equipment99.99% High Purity Gold Electrolysis From Gold Wet Way Purification

we specialize in new technology research and development, new machine research and development, technology promotion, production process and workshop design of various precious metal smelting, electrolysis and environmental protection, as well as all-round service businesses such as design and manufacturing of various professional customize equipment, overall workshop equipment installation, operator training, organization and guidance of trial production

Charactors:(1) Casting anode plate: the crude gold raw material with 99% gold content is melted into the medium frequency smelting furnace and cast into a gold electrolytic anode plate.

(2) Electrolyte preparation and waste electrolyte recovery: gold electrolyte is prepared by dissolving pure gold in aqua regia and diluting it with hydrochloric acid aqueous solution.

(3) Electrolysis: hang the anode plate into the gold electrolysis cell and start the gold electrolysis equipment for electrolysis.

The company's high-efficiency gold electrolysis unit (as shown in the figure) is developed based on years of experience in gold refining projects and customer suggestions. It adopts integrated and integrated design. The whole machine includes a single electrolytic cell, circulating pump, rectifier power supply, automatic electrolyte replenishment system, electrolytic flue gas condensation recovery system, electrolyte temperature, voltage, current The copper bar temperature intelligent monitoring system, the rectifier power supply is closed separately, isolated from the acid gas in the workshop, and has a long service life.

With a number of domestic patents and advanced technology, it has the following advantages:

① The product quality is stable and can meet the gold ingot standard of au99.99 (grade I) of Shanghai Gold Exchange; it can also produce gold ingots with purity of 99.99% according to the special needs of customers;

② Low production cost: about 0.02 yuan / gram gold;

③ The electrolysis adopts AC / DC superimposed power supply, which can effectively inhibit the generation of silver chloride on the gold anode and make the anode plate electrolysis more thorough;

④ High current density electrolysis technology; cathode current density up to 1200A / m2, high production efficiency;

⑤ The electrolytic cell is designed with a transparent closed smoke cover to prevent smoke from escaping, which is easy to operate and beautiful;

⑥ A flue gas condensing device is set. Due to the high temperature (60-70 ℃) required by the gold electrolysis process, the flue gas condensing device can condense the reflux volatile electrolyte to avoid the loss of gold;

The main material of the equipment is high performance polypropylene material, adding anti-aging agent to the material, which greatly prolongs the service life of the equipment. The whole bracket material is PPH, and the corrosion resistance is very strong; the cathode and anode conductive bar material is titanium coated copper with excellent conductivity.

This set of gold electrolysis unit is designed with PLC automatic operation system, controlled by touch screen, and has the function of electrolytic parameter storage. When the electrolytic voltage, current and copper bar temperature are abnormal, the rectifier power supply can be directly interlocked to stop. The whole set of equipment is simple, safe and convenient.No details machine name Specification material Unit quantity 1 Gold refining complete equipment gm-jdj-3 Electrolytic cell Non standard; Refining capacity 3kg / D PPH pcs 1 2 Magnetic pump MP-20RM Fluorine lining set 1 3 Conductive copper bar Non standard; The material is No. 1 red copper, and the specific size is according to the picture. Red copper set 1 4 Cathode and anode conductive bars Titanium clad copper titanium set 1 5 Electrolytic cathode Titanium plate (pure titanium) titanium set 1 6 High level tank 30L Glass set 1 7 condenser 1.5m2 Glass set 1 8 Titanium screws Rectifier power supply, heating, lighting, control panel titanium set 1 9 Electric control system Non standard; Material PPH combination set 1 10 Trough support Flat die, matching for gold electrolysis PPH pcs 1 11 Anode mould Specification and model High purity graphite set 5 -

silver electrolysis machine

silver electrolysis machineHigh Light: Electrolytic Silver Recovery System 99.99% Purity, 99.99% High Purity Silver Extraction Machine, 99.99% Electrolytic Silver Extraction Machine。

99.99% high-purity silver electrolysis machineThe silver electrolysis equipment produced by our company is the most advanced and efficient at present. We use the crude silver plate as the anode, the titanium plate as the cathode, the silver nitrate solution as the electrolyte, and then connect the DC power supply to dissolve the crude silver in the anode, and the pure silver precipitates in the cathode to improve the purity of silver, so as to refine the crude silver containing more than 97% silver to 99.99% high-purity silver.

The biggest advantage of product design:

1. A flue gas condensation system is set to cool the flue gas to avoid silver loss;

2. The main material of the equipment is high performance polypropylene material, adding anti-aging agent in the material, so that the service life of the equipment is greatly extended. The overall support is made of PPH with strong corrosion resistance; The cathode and anode conductive strips are made of titanium clad copper with excellent conductivity. -

gold electrolytic unit

gold electrolytic unitThe advantages of gold electrolytic unit include:

1、High purity: Electrolytic refining can result in gold purity of 99.99% or higher.

2、High efficiency: Compared to other refining methods, electrolytic refining can extract gold quickly and efficiently.

3、Non-toxic: Most of the chemicals used in the electrolytic refining process are non-toxic and non-hazardous substances, which are not harmful to the environment and human body.

4、Controllable: The process of electrolytic refining can be precisely controlled so that the purity and shape of the gold produced can be adjusted as required.

5、Wide applicability: Electrolytic efining is applicable to all kinds of gold content metals, from high grade gold ores to low grade gold bearing scrap.Advantages of gold refinery machines:

(1) Casting anode plate: the crude gold raw material with 99% gold content is melted into the medium frequency smelting furnace and cast into a gold electrolytic anode plate.

(2) Electrolyte preparation and waste electrolyte recovery: gold electrolyte is prepared by dissolving pure gold in aqua regia and diluting it with hydrochloric acid aqueous solution.

(3) Electrolysis: hang the anode plate into the gold electrolysis cell and start the gold electrolysis equipment for electrolysis.

The company's high-efficiency gold electrolysis unit (as shown in the figure) is developed based on years of experience in gold refining projects and customer suggestions. It adopts integrated and integrated design. The whole machine includes a single electrolytic cell, circulating pump, rectifier power supply, automatic electrolyte replenishment system, electrolytic flue gas condensation recovery system, electrolyte temperature, voltage, current The copper bar temperature intelligent monitoring system, the rectifier power supply is closed separately, isolated from the acid gas in the workshop, and has a long service life.

With a number of domestic patents and advanced technology, it has the following advantages:

① The product quality is stable and can meet the gold ingot standard of au99.99 (grade I) of Shanghai Gold Exchange; it can also produce gold ingots with purity of 99.999% according to the special needs of customers;

② Low production cost: about 0.02 yuan / gram gold;

③ The electrolysis adopts AC / DC superimposed power supply, which can effectively inhibit the generation of silver chloride on the gold anode and make the anode plate electrolysis more thorough;

④ High current density electrolysis technology; cathode current density up to 1200A / m2, high production efficiency;

⑤ The electrolytic cell is designed with a transparent closed smoke cover to prevent smoke from escaping, which is easy to operate and beautiful;

⑥ A flue gas condensing device is set. Due to the high temperature (60-70 ℃) required by the gold electrolysis process, the flue gas condensing device can condense the reflux volatile electrolyte to avoid the loss of gold;

The main material of the equipment is high performance polypropylene material, adding anti-aging agent to the material, which greatly prolongs the service life of the equipment. The whole bracket material is PPH, and the corrosion resistance is very strong; the cathode and anode conductive bar material is titanium coated copper with excellent conductivity.

This set of gold electrolysis unit is designed with PLC automatic operation system, controlled by touch screen, and has the function of electrolytic parameter storage. When the electrolytic voltage, current and copper bar temperature are abnormal, the rectifier power supply can be directly interlocked to stop. The whole set of equipment is simple, safe and convenient.

model number

external dimensions

ability to precipitate pure gold

power(kw)

power supply

material

JQ-JDJ-2.5

1000*700*1800mm

2.5kg/d

2

380V

PPH

JQ-JDJ-5

1000*700*1800mm

5kg/d

2

JQ-JDJ-10

1100*700*1800mm

10kg/d

4

JQ-JDJ-20

1700*800*1800mm

20kg/d

6

-

vacuum melting furnace

vacuum melting furnace1-4 kg capacity gold, silver, copper melting furnace

Power Supply; 220V Power: 3.5kw Maximum temperature: 1600 ℃ Applicable metals: gold, K gold, silver, copper, brass and their alloys Metal capacity: 1-4kg (gold) Dissolution time: 2-3min Overall dimension: 530 * 530 * 900 (mm) Body weight: 20kg