-

pickling agitating tank

pickling agitating tankFeatures of pickling agitating tank:

RJS pickling agitating tank is a kind of special equipment for removing the materials accumulated on the surface of activecarbon, such as calcium carbonate, by using the diluted hydrochloric acid. It is a kind of agitating tank improved on the basis of RJ agitating tank, With specially designed impeler, its abrasion to the carbon is low, Its shaft and impeller are made of stainless steel.

Notes for Selection

While placing your order, please specify the model and quantity, as well as the material of the tank. The tank many bemade of stainless steel or anticorrosion treated common steel plate, at the customer's option.

Technical parameter list of RJS pickling agitating tank

槽体尺寸(mm)

Size of trough

有效容积(m°)

Effective

volume

叶轮直径(mm)

Impeller Dia

转速(r/min)speed

电动机 Motor

外形尺寸(mm)

Dimension

(LxWxH)

机器总重

(kg)

Total weight

直径Dia

高度Heigh

型号

Model

功率(kW)

Power

1000

1000

0.7

240

238.3

Y100L-6

1.5

1198x1198x2130

531

1500

1500

2.2

400

142

Y132S-8

2.2

1798x1798x2880

955.4

-

electrowinning/electrorefining tank

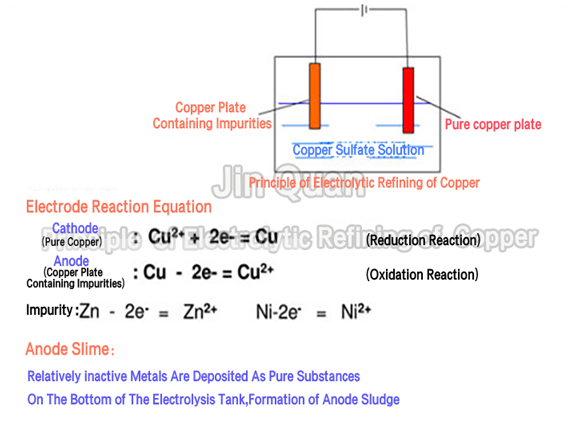

electrowinning/electrorefining tankRotating Electrode Technology and Conventional Electroplating Technology share the same electrochemical theoretical foundation. Both involve immersing the anode and cathode in an electrolyte solution containing target metal cations, achieving directed movement of ions under electric fields to deposit the target metal on the cathode.

The difference lies in that rotating electrode devices allow for higher flow velocity of the electrolyte solution, effectively utilizing the rapid flow of the electrolyte to eliminate concentration polarization phenomena during the electroplating process. This ensures more complete reaction and high purity of cathodic products with high current efficiency. It is particularly suitable for (wet metallurgical industry) in the selective electrolysis (electroplating) separation and purification of low-concentration and multi-component electrolyte solutions, or for removing metal ions from wastewater.

Applications:

1、Copper refining waste liquid purification;

2、Copper corrosion solutions copper recovery;

3、Zinc smelting slag copper and nickel recovery;

4、Copper, cobalt, nickel, zinc mixed metal ion solution copper, cobalt, nickel recovery;

5、Cyano solutions electrorefining Au and Ag recovery。

-

copper leaching system

copper leaching system1、Customer demand

The metal copper in copper ore is extracted by physical and chemical methods, and a theoretical and practical process is found for extracting copper from copper ore.

2. Basic customer data

Feed type

Copper production

Product shape

process mode

Solution copper content

Effluent copper content

20% copper ore concentrates powder

100 kg

Copper sulfate solution

Batch processing

5-20%

20g/L

Copper sulfate solution

100 kg

Electrolytic copper plate

Batch processing

10-40g/L

2g/L

3.Process introduction

The experiment was mainly carried out in three steps:

In the first step, the copper metal in the copper ore is dissolved in the liquid, and the solid copper metal is converted into the free ion state;

The second step, the solution of dissolved copper is filtered to remove impurities;

The third step is to extract and purify the copper in the copper containing solution. The result is a high purity copper sheet.

4.Experimental Process:

1.Configure the concentration of about 10% to 15% concentration of dilute sulfuric acid

solution standby.

2.A certain amount of copper ore is weighed and crushed, and the crushed copper ore powder is placed in dilute sulfuric acid. After the copper ore is put into dilute sulfuric acid,

a violent reaction occurs in the solution, some gas emerges, and the copper ore slowly dissolves. The color of the potion turns cloudy.

3.Add an appropriate amount of oxidant to accelerate the dissolution of copper in the ore powder.

4.After about 1 hour,the solution appears stratified, green clear liquid appears on the upper layer,and very colored insoluble solid or sludge appears on the bottom.

5.The precipitation was filtered and separated, and the green liquid was filtered out.

6.The copper content of the green filtrate was analyzed, and the concentration of copper ion reached 40g/L. High copper content.

7.The electrolysis experiment was carried out on the green copper filter liquid, with the filter

liquid as the electrolyte, titanium plate as the anode and stainless steel plate as the cathode.

8.A certain intensity current is applied to the anode and cathode plate for electrolysis, and a

copper substance appears on the cathode plate and is attached to the cathode stainless steel plate. Continue electrolysis.

-

copper recovery equipment

copper recovery equipmentThe copper electrolysis system uses the latest permanent cathode technology, completely replacing the Initial electrode plate electrolysis process; high-dimensional precision ethylene-base epoxy resin is used for the entire electrolysis tank, replacing the original glass electrolysis tank to accelerate material turnover.

Simultaneously, ground communication is added, enabling wireless information exchange between crane, machinery, and electrolysis tanks during assembly status; AGV small car intelligent transfer is adopted for output lines to optimize material transportation scheduling; constant brightness control and human body sensing technologies are applied to achieve smart lighting and reduce energy consumption; monitoring of equipment operation status, automatic generation of data reports and statistical analysis are implemented.

Copper Recovery Euipment Project Case:

High-density Copper Electrolysis Tank Model Marameters:

Model

Copper Output Capacity

Other

Power

Materials

JQ-JDJ-20

20kg/d

depending on operating conditions

380V

PPH

JQ-JDJ-50

50kg/d

JQ-JDJ-100

100kg/d

-

copper electrolysis testing machine

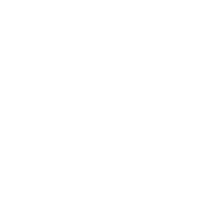

copper electrolysis testing machineThe raw material is 99.95% copper, used for experimenting in producing 99.999% pure copper. We need to design a copper electrolysis tank capable of producing 1 kilogram of copper per day.

Principle of Electrolytic Refining of Copper: