-

vacuum granulator

vacuum granulator20-50kg Vacuum Granulator (With Mechanical Stirring):

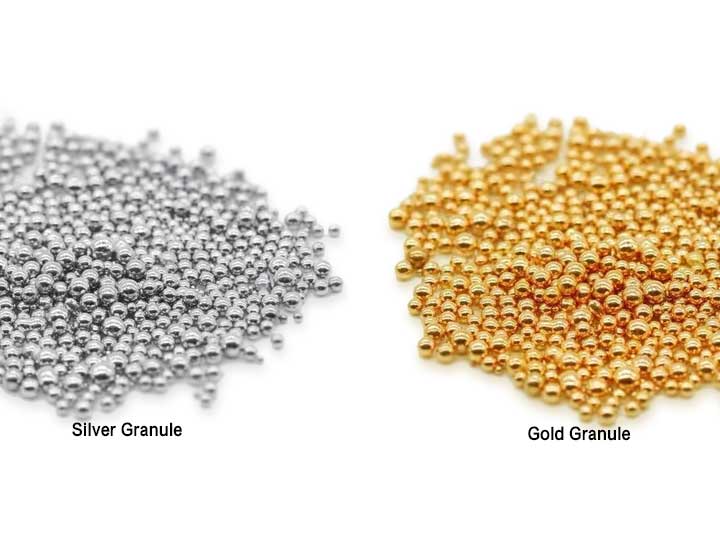

Anti-Oxidation: Inert gas protection during melting minimizes alloy oxidation.

Uniform Color: Mechanical stirring ensures even product coloration.

High-Quality Output: Vacuum granulation yields low oxygen content, no water trapping, and excellent sphericity.

Precise Temperature Control: Intelligent digital control with a temperature deviation of ±2°C.

Secondary Feeding: Allows additional material input under vacuum to ensure complete metal melting.

Next-Gen Operating System: User-friendly interface with streamlined one-touch operation.

Equipment Specifications:

Model

Voltage

Power

Max Temp

Melting Time

Gas Used

Max Capacity

Applicable Metals

Cooling

Vacuum Pump

Dimensions

Weight

JQ-GVS20

380V

30KW

1600°C

10min

Argon/Nitrogen

20KG(Gold)

Gold, Silver, Copper, Alloys, Aluminum, Tin, etc

Water-cooled

63m3 /hour

1180*1000*2050mm

~360KG

JQ-GVS30

380V

45KW

1600°C

12min

Argon/Nitrogen

20KG(Gold)

Gold, Silver, Copper, Alloys, Aluminum, Tin, etc

Water-cooled

63m3 /hour

1180*1000*2050mm

~380KG

JQ-GVS50

380V

75KW

1600°C

15min

Argon/Nitrogen

50KG(Gold)

Gold, Silver, Copper, Alloys, Aluminum, Tin, etc

Water-cooled

63m3 /hour

1180*1000*2050mm

~400KG

-

vacuum continuous casting machine

vacuum continuous casting machine1600 ℃ 4-8 kg induction heating type continuous cast equipment

1. Jewelry continuous casting device is specially developed for casting high-purity gold, K gold, silver and other precious metal plates, bars, rectangular bars, circular pipes and other products

2. It adopts gas protection melting, temperature control accuracy and automatic mixing function to let the surface of the finished product shining without any pores and oxidation

3. The best casting technology and top-level equipment engineering are used to achieve the best metallurgy and high precision. The continuous casting machine is extremely fast, reliable and cost-effective

model: LS-8 power: 380V, 50/60 hz, 25kw Maximum current: 26 A Applied metal: Gold, silver, copper, and their alloys Maximum capacity: 24k 8.0 kg; 18k 6.0 kg; 925 silver 4.0 kg smelting time: 8 min application: bar: diameter 4-20 mm pipe: min 9-12mm, max 52-60mm block: min T5xW5mm, max T20x W70mm maximum temperature: 1600 ℃ K-type thermocouple: 1100℃ Maximum pulling speed: 40 cm/min Machine size: 1120x840x1560 mm Machine weight: 205 kg Shielding gas: Nitrogen or argon heating system: induction heating Temperature control system: PID Temp Accuracy: +-2℃