-

Raw Materials for Precious Metal Refining Plants

Raw Materials for Precious Metal Refining PlantsRaw Materials for Precious Metal Refining Plants:

1、Gold and silver refining plants: Gold mud/charcoal with gold loading from cyanide solution after decomposition, obtained through electrowinning.

2、Lead refining plants: Lead anode sludge processed into gold-silver alloy boards.

3、Copper refining plants: Copper anode sludge processed into gold-silver alloy boards.

4、Raw gold and silver collected from other industries.

-

Disadvantages of Traditional Silver Electrowinning Units

Disadvantages of Traditional Silver Electrowinning UnitsDisadvantages of Traditional Silver Electrowinning Units:

1、Low Current Density: Typically, the cathode current density can only reach 300-400 A/m².

2、Unstable Silver Powder Mass: The mass of silver powder produced is unstable.

3、High Labor Intensity: The production, washing, and transportation of silver powder require a significant amount of labor.

4、Complex Residual Anode Handling Process: The process of handling residual anodes after electrolysis is complex.

5、High Energy Consumption with Upper Extraction Method: When using the upper extraction method, energy consumption is high, and wind efficiency is poor.

-

Golden Electrowinning Closed Loop Technology

Golden Electrowinning Closed Loop TechnologyGolden Refining Methods:

Gold refining has a long history, with electrolysis and the Wang water method being two classic techniques. The main advantage of the electrolysis method is that it can produce gold of 99.95% to 99.99% purity under relatively low investment. However, its main disadvantage is that a large amount of gold must be stored either in the form of ions in the electrolyte or on the electrodes, leading to significant capital investment for the electrolytic cells themselves. Additionally, the production rate of this method is slower than that of the Wang water method.

In the Wang water method, gold is dissolved in Wang water, and a chemical agent is used to partially reduce the gold present in the solution, resulting in 99.99% pure gold. Requirements:

The total soluble gold quantity in the solution must be known.

The acidity of reducing conditions should be appropriately adjusted.

Partial reduction is typically carried out at 80% to 90% of the theoretical value.

-

Dore Silver Refining Process

Dore Silver Refining ProcessSodium Chloride Precipitation Method:

Strictly speaking, this process is utilized for recovering silver from wasted electrolyte solutions rather than purification. It entails using sodium chloride to react with silver nitrate and precipitate silver chloride, thereby separating silver from other impurities. The precipitated silver is then reduced into silver powder using agents such as hydrazine, iron powder, and zinc powder. This silver powder is subsequently reacted with nitric acid to generate the corresponding silver electrolyte. Currently, many smelters employ this method.

-

Chloroauric Acid Leaching Method for Gold Refining

Chloroauric Acid Leaching Method for Gold RefiningChloroauric Acid Leaching Method for Gold Refining:

Leaching Process: This involves extracting gold from a chloroauric acid solution into an organic solvent, allowing other non-gold impurities to remain in the aqueous phase.

Reverse Leaching with HCl: After leaching, hydrochloric acid is used to separate gold from the organic phase by moving it into the aqueous phase.

Reduction of Precious Liquid: The precious liquid containing gold is then reduced to elemental gold.

-

To Reduce Loss in Gold Refining Process

To Reduce Loss in Gold Refining ProcessTo Reduce Loss in Gold Refining Process:

During the dissolution process, precious metals are lost through smoke and improve the effectiveness of smoke mist separation.

Gas bubbles generated during dissolution break at the surface of the reaction tank into small droplets that are carried into the smoke absorption tower with the smoke and dispersed in the liquid or air inside the absorption tower. These droplets contain ClAu3+ and acid, leading to gold loss. Therefore, we need to control the amount of smoke generated from the reaction tank and install a gas-liquid separator to collect liquids for recycling or return them to the reaction tank.

For a company performing gold refining using a chemical method, several grams of gold can be directly recovered during the treatment of one batch of gold.

Gas-liquid separators should be installed on both the dissolution and reduction reaction tanks to recover gold and enhance acid efficiency while reducing the amount of reagents used for smoke treatment.

-

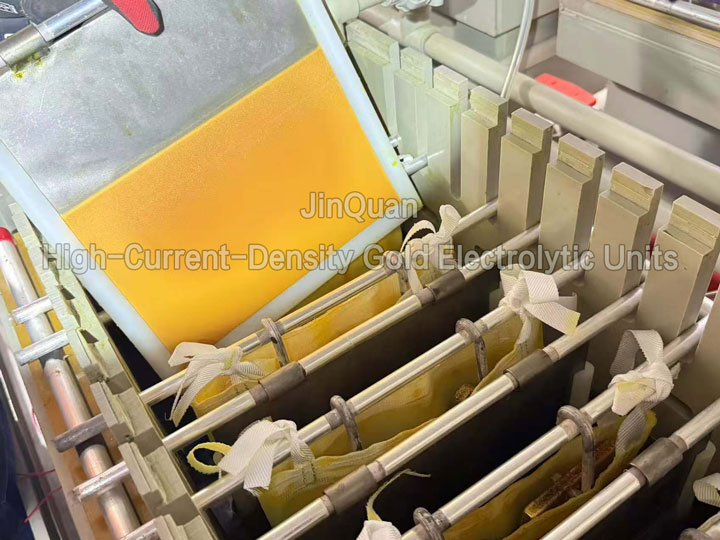

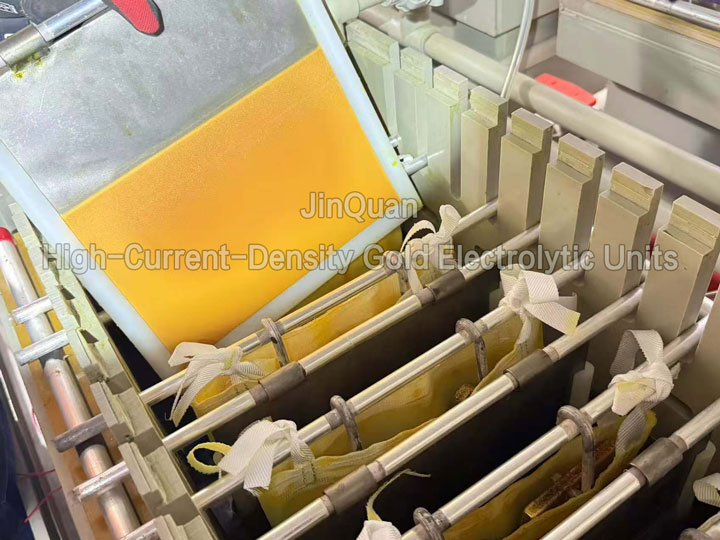

high-current-density gold electrolytic units

high-current-density gold electrolytic unitsCharacteristics of High-Current-Density Gold Electrolytic Units:

A. The high current density of this cell design allows for shorter operation cycles per unit weight of the anode, accelerating capital turnover.

B. The electrolyte circulates in parallel with a downward and upward flow pattern. The liquid flows parallel to the electrodes within the entire electrolytic cell, ensuring uniform ion diffusion.

C. A large volume of electrolyte circulates, enhancing ion diffusion speed and minimizing concentration polarization.

D. A screw connection is used between the cathode and mother liquid outlet, ensuring excellent electrical conductivity.

E. The electrolytic cells are arranged in parallel configuration.

-

gold electrolysis refining

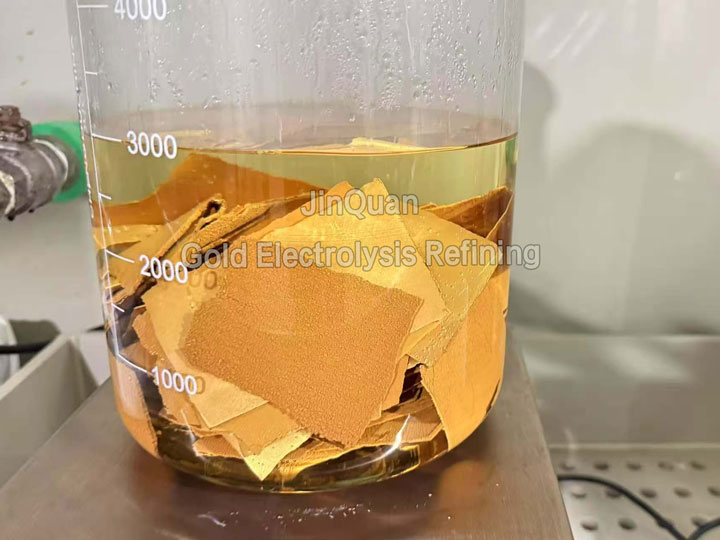

gold electrolysis refiningGold Electrolysis Refining:

In China, the technology for refining gold using electrolysis has been practiced for some time. Typically, the current density at the cathode is 300 A/m², with the concentration of gold in the electrolyte reaching 300 g/L. Major companies employing this method include Sichuan Changcheng and Inner Mongolia Qianyun, as well as various non-ferrous metal refineries such as Shenyang Refinery/HSBC/Hubei-Yichuan Refinery. The cathode has a relatively long cycle time, leading to significant gold accumulation in the process.

Since around 2000, high-current-density gold electrolytic cells have been introduced into China. These cells feature a cathode current density of 1200 A/m² and an electrolyte gold concentration ranging between 100-150 g/L. This advancement has enhanced production efficiency, reduced gold accumulation in the process, and streamlined operations.

-

how to refine silver to 999

how to refine silver to 999The Oxidized Silver Method: This is a method for producing high-purity white silver that involves the purification of silver electrolyte solutions. It has the advantages of short reaction time, one-step removal of multiple impurity ions such as copper, lead, iron, gallium, and antimony, minimal precious metal loss, and no introduction of new impurities during the purification process. This method is superior to other purification technologies, such as hot decomposition methods or other cleaning techniques, in terms of cost reduction, process simplification, and elimination of hazardous gas emissions like nitrogen oxide.

It also improves silver's collection rate and recovery rate (can increase by 0.3-0.6%) while reducing workers' labor intensity and enhancing safety factors. This approach is characterized by its simplicity, short purification time, recyclable electrolyte, minimal precious metal loss, low production costs, and no environmental hazards. It represents a multifaceted solution that has been promoted for use in our company. Currently, Anshan Mountain Copper, Yong Xin Jiao Jin, and other enterprises are using this technology.